BAE Graduate Student Shows that Statistics are Worth the Effort in Food Safety

Ph.D. candidate Ian Hildebrandt has taken on the challenge of taking research from the lab scale to industry.

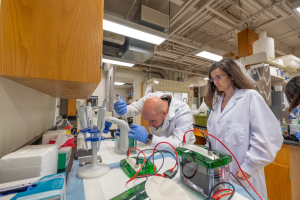

In a lab-scale setting is how many aspects of food safety research take place. The challenge with taking research from the lab to the industry is scaling it up without creating too much difference in the variability of outcomes. This is the challenge Ian Hildebrandt has set out to answer throughout his academic and professional career.

In a lab-scale setting is how many aspects of food safety research take place. The challenge with taking research from the lab to the industry is scaling it up without creating too much difference in the variability of outcomes. This is the challenge Ian Hildebrandt has set out to answer throughout his academic and professional career.

Hildebrandt always knew he was interested in health as a career, but he was not interested in becoming a medical doctor like his father. While participating in an MSU Alumni Distinguished Scholarship (ADS) tour of the Biosystems and Agricultural Engineering (BAE) department, Hildebrandt met with Dr. Bradley Marks and found his calling. During his undergraduate degree, Hildebrandt worked in Dr. Marks's lab, looking at food safety issues surrounding meat products. After completing a Bachelor of Science in Biosystems Engineering, Hildebrandt completed a Masters Degree in Biosystems Engineering: Food Safety before entering the workforce for two years with the FDA. During his career with the FDA, Hildebrandt worked with organizations like MSU and the Illinois Institute of Technology's, Institute for Food Safety and Health (IFSH).

I have worked on improving food safety in collaboration with many institutions; I knew returning to MSU would enable me to make the biggest impact possible." Hildebrant said.

Organizations such as the Almond Board of California provided data to Hildebrandt for his Ph.D. project, which allowed him to have a more thorough data pool to gain insights. The Almond Board of California regulates all almond processes and has documentation of validation reports covering the last thirteen years.

With concerns about invalidating your processes and deeming them unsafe, organizations tend to be intimidated by embracing statistics. Hildebrandt's Ph.D. work focuses on the statistical analysis of data provided by organizations such as the Almond Board of California to improve validation guidelines used to ensure their food products are safe.

To help combat the perception that statistics are not worth the effort, Hildebrandt participates in workshops and speaks to groups about statistics and variability. He presented his research at the 2022 Almond Quality Symposium hosted on July 23 in Lodi, California, where he talked about meta-analysis of almond pasteurization validations.

A lot of industry professionals do not want to think of their processes as variable" Hildebrant said. "However, processors who understand that variability is unavoidable can use that information to make their food safer for consumers.

The results are starting to come to fruition, as after a presentation this summer, Hildebrandt had two process authorities come up and compliment his work. He was also asked to return to California in December to present his work to a broader audience.

Knowing that my work on process validation is making an immediate impact is the type of validation I needed." Hildebrant said.

Hildebrandt hopes that in the long term, his work will show industries that statistics are a more accurate method of determining variability and should not be intimidated. This would lead to updating guidelines across various industries, which would be win-win. By reassuring consumers of the safety of their food, businesses can have accurate and reliable food processing methods.

Print

Print Email

Email