EAST LANSING, Mich. — The Michigan State University (MSU) School of Packaging has announced the formation of a Packaging Distribution Consortium prompted by its acquisition of two pieces of equipment that represent new package hazard simulation technologies. This group of industry thought leaders will guide cutting edge research focused initially on multi-axis vibration and lateral acceleration dynamics. The results of the research will be used as the basis for the development of new, deployable International Safe Transit Association (ISTA) test and simulation methods that address those unique dynamics, all in pursuit of optimized transport packaging solutions.

“The time is right for MSU to lead out with this consortium. We will have the new equipment, faculty and proximity to the ISTA headquarters to successfully drive new research that will benefit industry and develop the next generation of distribution packaging experts,” said Matt Daum, Ph.D., director and professor of the MSU School of Packaging and CANR assistant dean for corporate relations and strategy.

The MSU School of Packaging has been a pioneer in developing, implementing, and teaching advanced knowledge in distribution dynamics. In the 1960s, this research resulted in the application of Damage Boundary Theory to Product Fragility which led to substantial improvements in both product and package design.

"Many test standards in place today originated from research conducted by MSU faculty. Now, with the advent of multi-axis vibration technology, the industry is in need of groundbreaking research to propel new insight leading toward the next generation of industry practice and consensus test standards,” Daum explained.

The consortium will provide guidance and feedback to School of Packaging researchers for distribution packaging curriculum and obtain access to graduate students focused in the distribution packaging area. Research projects published for public domain use will help shape consensus and standard development.

The consortium’s research will be led by MSU School of Packaging Assistant Professor Amin Joodaky, Ph.D., as principal investigator. With a Ph.D. in mechanical engineering from Purdue University, Joodaky will lead a team of post-doctoral fellows, graduate students, the Consortium Advisory Council, and ISTA representatives, in consultation with external academic and private subject matter experts. The consortium will also foster interdisciplinary relationships with the MSU College of Engineering and the MSU Department of Supply Chain Management in the Broad College of Business.

Daum will sponsor the consortium and Dwight Schmidt, School of Packaging alumnus and consultant emeritus, will chair the effort.

Pre-shipment testing is routinely conducted to evaluate the ability of a package to withstand the rigors of its supply chain,” Schmidt said. "The focus of the consortium will be on developing methodologies to address existing distribution hazards, notably multi-axis vibration and horizontal acceleration, that are not currently being replicated during this process. We have developed a prospectus that details the consortium’s purpose, value and research direction that I am eager to share with potential members."

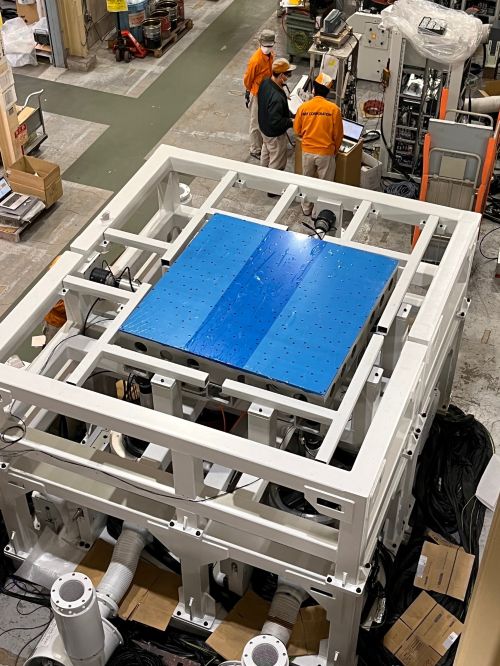

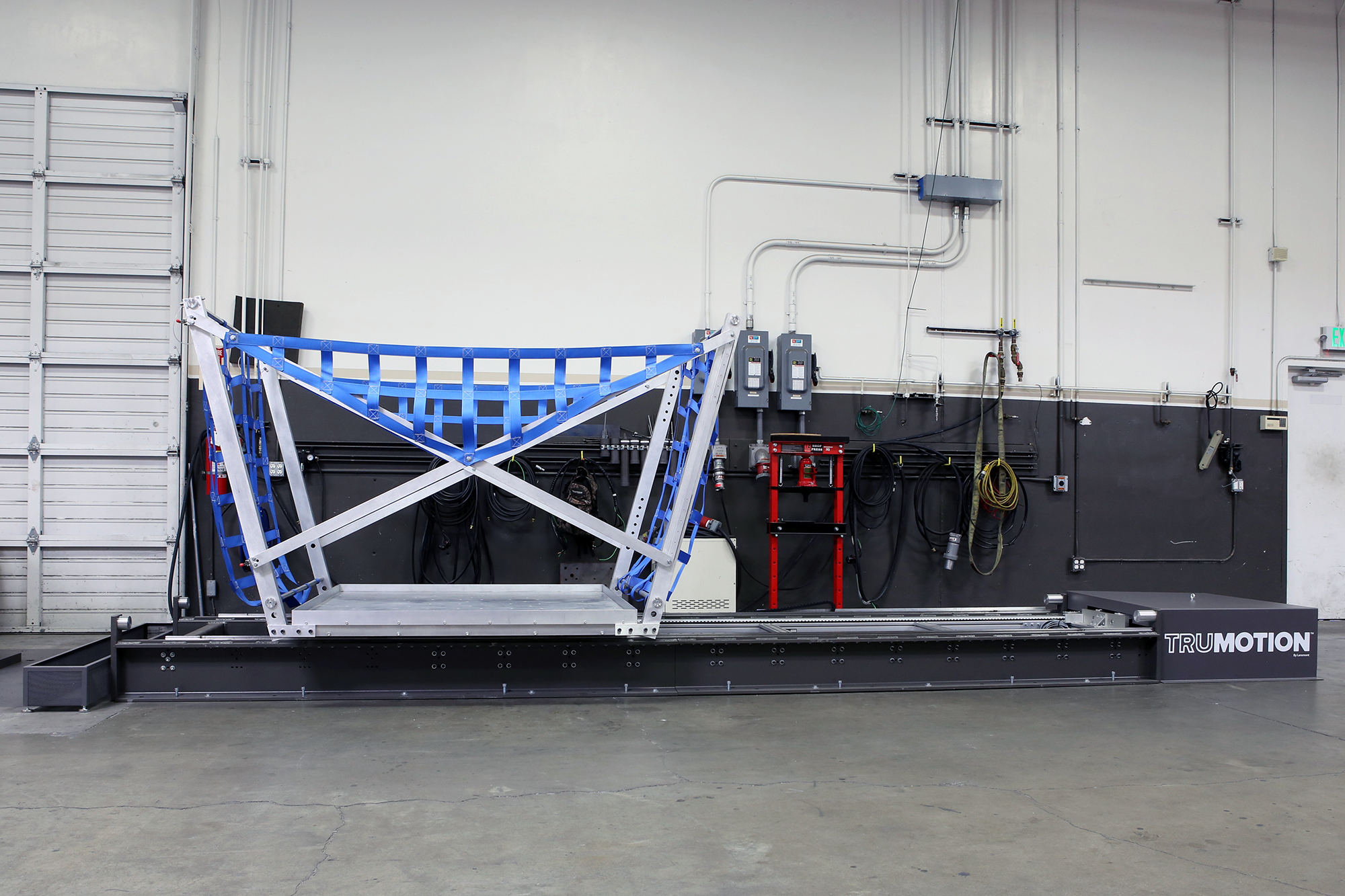

MSU will be the only packaging program in the country with a multi-axis vibration table dedicated to packaging applications. The multi-axis vibration equipment, donated by IMV, is designed to replicate the motions packages and unit loads are subjected to in transit. It will be complimented by a Lansmont donation of a TruMotion® horizontal acceleration sled, which gives the ability to duplicate starting, stopping and turning motions.

This equipment, combined with the school faculty’s background and expertise in advanced dynamics and transportation testing, will support cutting edge research. The school is also fortunate to be in close proximity to ISTA, the industry’s leading test standards organization for distribution dynamics thought leadership. MSU’s collaborative approach will bring together the brightest minds to forge new insight and value for industry by developing new test methodologies leading to new test standards, while simultaneously developing and training students for careers in distribution dynamics.

“I am anxiously awaiting for the installation this summer of these two unique assets our donors have provided and I am looking forward to coordinating this cutting edge research program starting in August,” Schmidt said.

Operating under a set of bylaws that meet university standards, the consortium will address the needs and rights of its members covering its operation, confidentiality, and intellectual property ownership. Three levels of membership with varying benefits are available with a three-year pledge: Platinum (voting) at $50,000 per year, Gold at $15,000 per year and NGO membership by invitation only. All membership fees will be considered a tax-deductible gift to the university.

Housed within the College of Agriculture and Natural Resources, the top-ranked MSU School of Packaging is the first school of packaging in the United States and the largest packaging program in the country, with approximately 600 total undergraduate and graduate students. Each year the School of Packaging graduates nearly 40% of packaging engineers in the U.S. It is the only school that offers a Ph.D. program in packaging and boasts 10,000 alumni worldwide. The school’s faculty members conduct research and teach in diverse industries such as medical, food, industrial packaging, packaging sustainability and lifecycle analysis, packaging design, bio-polymers, logistics optimization, and distribution dynamics.

For more information on the MSU School of Packaging Distribution Consortium and membership benefits, please contact Schmidt at dwight@consultschmidt.com.

Print

Print Email

Email