Pesticide drift and chemigation: friend or foe to water quality

Pesticide drift and chemigation when not properly used or contained can pose great risk to water quality.

The movement of pesticides off the target organism can have a tremendous impact on water quality. The obvious mode of contamination is direct contact through runoff, leaching or accidental spillage. There are two other methods of pesticide and water interaction that can cause an effect water quality, chemigation and pesticide drift.

Chemigation is the practice of injecting chemicals through irrigation systems. This practice is an excellent means of applying pesticides. Not all pesticides can legally be applied through chemigation, so farmers need to read the pesticide label carefully. One of the benefits of chemigation is a more uniform application of the pesticide; growers should check their irrigation systems uniformity every three to five years. There is also less damage to the crops caused by machinery and hazards to farmers are reduced. The downside of chemigation is the equipment. Growers who use chemigation need to closely monitor the irrigation system to make sure that all backflow devices are effective and working properly. The pesticide must not be injected on the suction side of the pump. The pesticide must not be injected on the suction side of the pump. This is not a common or legal practice since it offers no means of backflow protection. When using chemigation growers should apply the minimum amount of water to ensure proper pesticide application, but not too much water where there is potential for runoff or leaching. To ensure there is no drift, wind speed and direction needs to be closely monitored and if the wind speed is over five miles per hour chemigation should not be used. In Michigan, farmers who chemigate should refer to Michigan State University (MSU) Extension Bulletin E-2349, “Protect Your Water Supply From Agricultural Chemical Backflow” by Dr. Robert Wilkinson. Michigan growers should also familiarize their selves with the Irrigation Generally Accepted Agriculture Management Practices.

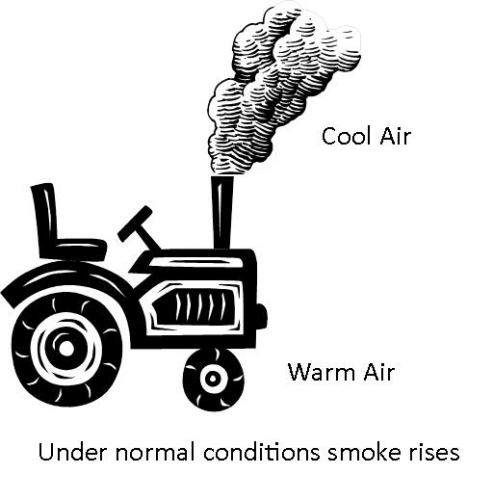

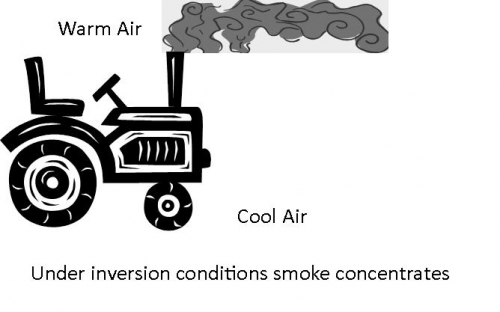

Pesticide drift is the movement of pesticide off target by wind or air currents. Drift can be in the form of vapor, particles or spray. Spray drift occurs when liquid pesticide leaves the intended area. To minimize spray drift, growers should try to use the largest spray droplet size they can as well as ensure that wind speed and direction do not carry spray off of the site. Different pesticide formulations can also increase or decrease droplet size. Spray drift can also occur during temperature inversions. This happens when the air is warmer than the soil surface. The warm air traps the cooler air at the surface, at this point the air is considered stable because there is little vertical movement of air. The problem is with lateral movement of air. In temperature inversions, pesticide drift can move great distances laterally and as the wind increases spray droplets can be released. Temperature inversions can occur at anytime of the day, but the risk is higher in the evening and early morning.

Vapor drift is the movement of pesticide through gaseous vapors. Pesticides with high volatilization have the potential of vapor drift. As temperature increases during the day, liquid can turn into gas and drift. Vapor drift may travel farther and be sustained longer in the environment than spray drift. For this reason, farmers should use the chemical with the lowest volatilization rate as possible and not spray on hot days. Please be aware that some product can volatilize hours after application, so be aware of the possibility when spraying during hot weather. Read the pesticide label for rules of when to apply the pesticide.

Particle drift is when dust or soil particles with pesticide attached are moved offsite. Pesticide can remain on the particles for an extended time and continue to be active. To decrease the risk of contamination applicators should clean equipment, both machinery and personal protective equipment, before they leave the field. Farmers need to be aware of any sensitive areas: homes, schools, hospitals, etc. and remove contaminated clothing before they enter. They also should be aware of any surface water and make sure that when they apply pesticide the wind is blowing away from the surface body.

Print

Print Email

Email