Time is money when hauling manure

Haul manure nutrients up to 14 miles and recover costs with large spreader tanks and nurse trucks.

Manure agitation, pumping, transport and land application costs are typically $100-$160/cow/yr for a Michigan dairy farm. Because hauling and land application greatly impact labor needs and must align with tillage and planting plans, many farm managers custom-hire manure hauling services. Tank spreaders and tank spreader/nurse truck systems are common in Michigan because they are convenient for small fields and fields that are far from the manure storage site. Farm managers often ask, “how far can I haul liquid manure and recover their machinery ownership and operating costs?”

Tank spreaders over-the-road

The hauling rate (gallons per hour) with a tank spreader drops off quickly as the hauling distance increases. In our recent evaluation of tractor-drawn tank spreaders, the hauling rate fell by 20% with a one mile haul, 40% with a two mile haul and 50% with a three mile haul.

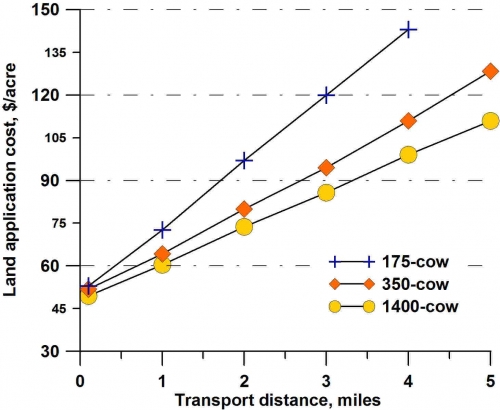

The total cost for pumping, agitation, hauling and land

application with subsurface injection for top-loading tank spreaders was 1.22

cents per gallon (¢/gal) for a 175-cow herd, and 1.34 and 1.48 ¢/gal for 350-

and 1400-cow herds, respectively. When manure was  applied at 7,000

gallons per acre (gal/ac) the hauling cost was about $50/acre per acre for each

of the herds when the fields were next to the storage pit, but as the hauling

distance increased the cost increased at a faster rate for the smaller herds

(Figure 1). Land application costs increased to $143/acre with a four-mile haul

for the 175-cow herd, $128/acre with a five-mile haul for the 350-cow herd, and

$111/acre with a five-mile haul for the 1,400-cow herd.

applied at 7,000

gallons per acre (gal/ac) the hauling cost was about $50/acre per acre for each

of the herds when the fields were next to the storage pit, but as the hauling

distance increased the cost increased at a faster rate for the smaller herds

(Figure 1). Land application costs increased to $143/acre with a four-mile haul

for the 175-cow herd, $128/acre with a five-mile haul for the 350-cow herd, and

$111/acre with a five-mile haul for the 1,400-cow herd.

- The spreader

tanks were selected to complete annual hauling operations in about twenty

10-hour days for each herd.

- A 3,000-gallon tank was used for the 175-cow herd.

- A 7,500-gallon tank was used for the 350-cow herd.

- Four, 9,000 gallon tanks were used for the 1,400-cow herd.

- A six-point injector was used with each spreader.

- Equipment ownership and operating costs were $96, $154 and

$633/hour for the 175-, 350- and 1,400-cow herds, respectively.

The breakeven hauling distance – the distance where the value of nutrients applied equals the cost of hauling – depends on the machinery set used, the nutrient content of the manure and the value of the nutrient credit that the farm manager gives to the manure. The value of the nutrient credit can be less than the total nutrient value in the spreader tank for many reasons: manure nitrogen may be unavailable for crop growth, manure nutrients may not be uniformity applied, the balance of nitrogen (N), phosphorus (P) and potassium (K) may not match crop needs, etc. Based on a value of $0.50 per pound for commercial N, P and K, the total value of liquid dairy manure with an analysis of 24-18-29 is about $36 per 1000 gallons. If a farm manager gives a conservative nutrient credit of 75% of the total nutrient value, the credit for calculating a breakeven hauling distance would be $27 per 1,000 gallons.

Based on an application rate of 7,000 gal/ac, ownership and operating costs of $96/hour and a nutrient credit of $27 per 1,000 gallons, the breakeven hauling distance was eight miles for the 3,000 gallon spreader.

Because the larger tanks hauled more nutrients, the breakeven hauling distance was 13 miles for the 7,500 gallon spreader and 14½ miles for the 9,000 gallon spreaders.

Nurse trucks over-the-road, tank spreader in the field

Manure hauling operations must align with other field work to make efficient use of equipment and labor and prevent delays in field operations, typically being hauled in spring and fall. Semi-tractor-drawn nurse tanks for over-the-road transport can provide flexibility in scheduling field operations and increase the productivity of tractor-drawn tank spreaders when applying manure to fields a few miles from storage. A typical hourly charge for custom hire of a large nurse truck is about $100/hr.

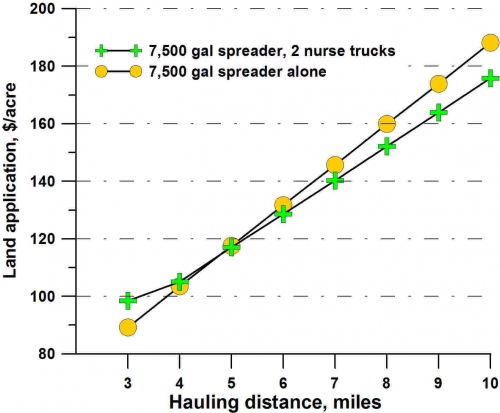

Custom hire of nurse trucks can greatly improve hauling

productivity. Consider, for example, the 7,500 gallon spreader tank used with the

350-cow dairy. When hauling three miles the hauling

rate was about 12,100 gallons per hour. When the spreader  tank stayed in the

field and two 7,500 gallon nurse trucks hauled from the pit to the field, the

hauling rate was 25,200 gallons per hour. Machinery costs increased from

$154/hour to $354/hour with the custom hire of two nurse trucks, but the increased

cost was more than offset by the increase in the hauling rate. When hauling three

miles the cost was about $98/acre with the tank spreader and nurse trucks, and

$89/acre with the tank spreader alone (Figure 2). When hauling five miles the cost

for each hauling system was $117/acre. When hauling 10 miles the cost for the

tank spreader with nurse trucks was $176/acre, the cost for the 7,500 gallon

tank spreader alone was $188/acre.

tank stayed in the

field and two 7,500 gallon nurse trucks hauled from the pit to the field, the

hauling rate was 25,200 gallons per hour. Machinery costs increased from

$154/hour to $354/hour with the custom hire of two nurse trucks, but the increased

cost was more than offset by the increase in the hauling rate. When hauling three

miles the cost was about $98/acre with the tank spreader and nurse trucks, and

$89/acre with the tank spreader alone (Figure 2). When hauling five miles the cost

for each hauling system was $117/acre. When hauling 10 miles the cost for the

tank spreader with nurse trucks was $176/acre, the cost for the 7,500 gallon

tank spreader alone was $188/acre.

The breakeven hauling distance for the 7,500 gallon spreader tank with two 7,500 gallon nurse trucks was 11 miles.

For additional information about the economic analysis see:

- Efficient Liquid Manure Transport

and Land Application

- Liquid Manure Hauling Capacity of

Custom Applicators Using Tank Spreader Systems

- Economic Comparison of Liquid Manure

Transport and Land Application

Special thanks to Natalie Rector, MSU Extension, for reviewing and providing constructive comments for this article.

Print

Print Email

Email