Vanilla is a forest industry by-product

Imitation vanilla flavoring can be created using by-products created during the paper making process.

Over the years, people have associated vanilla flavoring with the wood products industry when giving presentations about what we might not have if we stopped utilizing wood. This was surprising, as I had always considered vanilla to be a product of an orchid grown in the tropics. How could wood use in Michigan affect the availability of vanilla flavoring? As a Natural Resource Educator for Michigan State University Extension, it is time to investigate this claim, once and for all.

History of vanilla

According to a report published by the Food and Agriculture Organization (FAO) of the United Nations, the first recorded history of vanilla use dates to 1427-1440 AD, when the Aztecs conquered the Totonacan empire. The Aztecs then began to use vanilla in a chocolate drink made for noble families; the Spaniards took vanilla flavoring to Europe after invading the Aztec empire in 1519. The orchids that produce the seed pods used in making vanilla flavoring eventually made their way across the Atlantic Ocean to Europe, and finally to Madagascar in 1850, where it continues to be a valuable crop grown in Central and South America and African Countries.

How pure vanilla extract is made

According to the FAO report, there are over 110 vanilla orchid species distributed throughout the tropics. The flat-leaved vanilla orchid, or Vanilla planifolia, is the most important and studied species, with three main cultivars used worldwide in the production of real vanilla extract. To produce the flavoring, the seed pods produced by the orchid are soaked in alcohol to extract the flavor. The brown color comes from the essential oils that are also leached into the extracting alcohol. There are both heat and cold extracting processes; the process using heat preserves more of the aromatic compounds inherent in vanilla.

How artificial vanilla extract is made

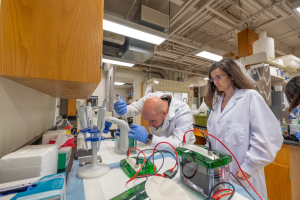

Because the vanilla orchid requires large plots of land and intense labor to produce the prized seed pods used in making real vanilla extract, scientists took to the laboratory to isolate, then synthetically replicate the vanilla bean flavoring component, called vanillan, in 1858. In 1874, two German chemists found they could replicate vanillan using chemical compounds from coal. It was also synthesized using coniferin, the glucoside that makes pines smell a little like vanilla. By the 1930’s artificial, or imitation vanilla was used in most households. Also, by the 1930’s coal was determined to be a carcinogenic, and was no longer widely used in the production of artificial vanilla extract in the US, where federal regulations prohibit it.

Instead, vanilla is chemically synthesized from the essential oil of cloves, or made from lignin, which is a byproduct of paper manufacturing. The lignin is chemically treated to resemble the taste of real vanilla. More recently, vanilla extract was made using rice bran extract, a product that quickly became the favorite of large corporations using vanilla flavoring because of its taste and low cost.

Now we know. Imitation vanilla flavoring is made from lignin, among other things, and can be considered a by-product of the forest products industry.

Print

Print Email

Email