Bulletin E3038

Flaming as a Method of Weed Control in Organic Farming Systems

DOWNLOAD

April 2, 2012 - Dale Mutch

Introduction

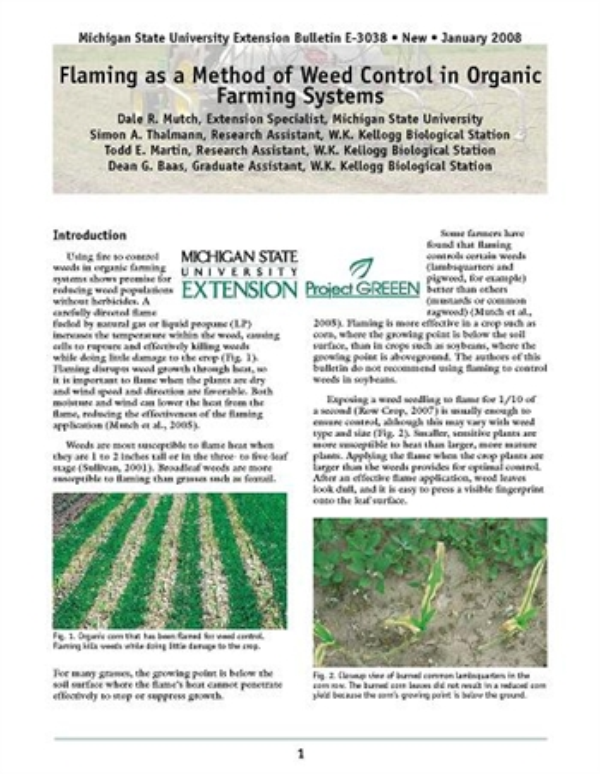

Using fire to control weeds in organic farming systems shows promise for reducing weed populations without herbicides. A carefully directed flame fueled by natural gas or liquid propane (LP) increases the temperature within the weed, causing cells to rupture and effectively killing weeds while doing little damage to the crop (Fig. 1). Flaming disrupts weed growth through heat, so it is important to flame when the plants are dry and wind speed and direction are favorable. Both moisture and wind can lower the heat from the flame, reducing the effectiveness of the flaming application (Mutch et al., 2005).

Figure 1. Organic corn that has been flamed for weed control. Flaming kills weeds while doing little damage to the crop.

Weeds are most susceptible to flame heat when they are 1 to 2 inches tall or in the three- to five-leaf stage (Sullivan, 2001). Broadleaf weeds are more susceptible to flaming than grasses such as foxtail.

Some farmers have found that flaming controls certain weeds (lambsquarters and pigweed, for example) better than others (mustards or common ragweed) (Mutch et al., 2005). Flaming is more effective in a crop such as corn, where the growing point is below the soil surface, than in crops such as soybeans, where the growing point is aboveground. The authors of this bulletin do not recommend using flaming to control weeds in soybeans.

Exposing a weed seedling to flame for 1/10 of a second (Row Crop, 2007) is usually enough to ensure control, although this may vary with weed type and size (Fig. 2). Smaller, sensitive plants are more susceptible to heat than larger, more mature plants. Applying the flame when the crop plants are larger than the weeds provides for optimal control. After an effective flame application, weed leaves look dull, and it is easy to press a visible fingerprint onto the leaf surface.

Figure 2. Closeup view of burned common lambsquarters in the corn row. The burned corn leaves did not result in a reduced corn yield because the corn’s growing point is below the ground.

Methods and research

A Michigan State University W.K. Kellogg Biological Station (KBS) study examined the effectiveness of postemergence weed control by cross-flaming (Fig. 3). Cross-flaming burners are set at an angle 30 to 60 degrees from horizontal and 4 to 10 inches away from and perpendicular to the crop. Gas pressures are typically operated between 25 and 70 pounds per square inch (PSI).

Figure 3. Cross-flaming in organic corn. In this system of flaming, the torches are generally staggered while flaming so that each does not interfere with the flame from the opposite burner.

Torches are staggered to limit interference between flames. This allows the heat to be directed into the crop from both sides. This provides more complete coverage and allows for greater application speeds, ranging between 2.5 and 5 mph. In general, flame application LP gas usage averages 8 to 10 gallons per acre, depending on application speed (Sullivan, 2001).

The two-year KBS study evaluated the effectiveness of flaming by comparing three treatments (Table 1) for weed control in organic corn systems. The treatments used were flaming, rotary hoeing (Fig. 4), and rescue treatments for early- and late-planted corn. Rescue treatments were late-season flaming when prior weed control measures had not been undertaken. All treatments were cultivated as needed in addition to the weed control treatments under evaluation.

Table 1. Weed control treatments

|

Trt |

Weed Control |

|

1 |

Rotary hoe as needed, cultivate |

|

2 |

Flame as needed, cultivate |

|

3 |

Rescue, late flaming, cultivate |

Figure 4. Rotary hoeing weeds in organic corn.

The three weed control treatments were evaluated each year in early- and late-planted corn. Prior to planting, plots were tilled three times using the methods given in Table 2 as required to provide consistent seed beds.

Table 2. Preplant tillage

|

Pass |

Tillage method |

|

1 |

Chisel plow or field cultivator |

|

2 |

Disk or field cultivator |

|

3 |

Field cultivator |

The three treatments were applied to corn planted early and late in a randomized complete block design with three replications. In 2005, early and late planting occurred on May 6 and May 18, respectively. In 2006, early planting occurred on May 8 and late planting on May 23.

Results

Figures 5 and 6 summarize the timing, treatments, weed control operations, mean yield and weekly precipitation for the three treatments of early- and late-planted corn in 2005 and 2006.

Figure 5. Summary of 2005 weed control treatments (means with the same letter are not significantly different at the p < 0.025 level; LSD @ = 10.7).

Figure 6. Summary of 2006 weed control treatments (means with the same letter are not significantly different at the p < 0.025 level; LSD @ 0.025 = 16.5).

There was no significant difference (at p < 0.025) in corn yield between years, when averaged over planting dates and years. However, the yield of late-planted corn in 2006 was significantly higher than the yields of early-planted corn. There was no difference in corn yield between early- and lateplanted corn in 2005.

Figure 7 shows the results of the weed control treatments by planting date and year. In general, the results of flaming and rotary hoeing were not different from each other with the exception of the late-planted corn in 2005. The yields resulting from rescue treatments in 2005 were not different from those of the rotary hoeing and flaming except in late-planted corn in 2005. The yields resulting from rescue treatments in 2006 were different from rotary hoeing and flaming within respective plant dates but were not different from rotary hoeing or flaming for other planting dates.

Figure 7. Weed control treatment effects including year and planting date interactions (means with the same letter are not significantly different at the p < 0.025 level; LSD @ 0.025 = 16.5).

Discussion:

2005 crop season

In 2005, the total precipitation from April through October was 15.5 inches. As shown in Figure 5, the spring prior to both the early and late planting dates was dry, as was the period from late July to early September. This lack of moisture resulted in reduced weed emergence. All three weed control treatments provided similar weed control under these dry growing conditions. However, corn that was flamed late in 2005 had a lower yield than corn with all other 2005 treatments except early rotary hoeing. Late flaming under the dry conditions may have led to some incidental damage to the corn crop. The reduced number of weed control operations (three versus four or five) appears to provide an advantage for the rescue treatment under dry growing conditions.

2006 crop season

In 2006, there were no statistical differences between mean yields for corn treated by flaming and rotary hoeing within planting dates. Rescue mean yields were statistically different from both flaming and rotary hoe corn yields at each planting date. The mean yields under the rescue treatments were 25 to 30 bushels per acre less than the yields of corn receiving the rotary hoe and flame treatments. In 2006, the total precipitation from April through October was 27.7 inches and evenly distributed through the growing season (Fig. 6). With adequate moisture, the advantage of early weed removal is evident in the increased yields for the flame and rotary hoe treatments versus the rescue treatment.

Combined 2005 and 2006 crop seasons

Combining data from 2005 and 2006 shows the same trends observed in the individual years. Early and late planting dates mean yields (76 and 68 bushels per acre, respectively) statistically differed by 8 bushels per acre (LSD @ 0.025 = 7). Overall, the mean yield for the flame treatment at 73 bushels per acre was not statistically different from that of the rotary hoe treatment at 77 bushels per acre. However, mean yield for the rescue treatment at 65 bushels per acre was less than the yield in the rotary hoe and flame treatments at the p < 0.025 level.

Conclusions

On a well-drained sandy loam soil, corn yields were similar when weeds were controlled with rotary hoeing or flaming treatments (Figure 7). Corn yield was reduced when late “rescue” weed control was attempted in wetter years.

Flaming offers a number of advantages over the more widely used organic weed control practice of rotary hoeing. Rotary hoeing can be impractical in shallow or dense claypan soils; flames can be applied in systems with any soil type or depth. Rotary hoeing also depends on dry soil conditions; flame application is not as affected by weather variability. Flaming is also less invasive, preserving soil structure and leaving crop roots unharmed.

Though there are many benefits to applying flames to control weeds in organic systems, there are also downsides. Optimal weed control often requires multiple flame applications, with little or no residual weed control effects. Flame applications must be timed precisely to effectively kill weeds, and weeds that emerge with the crop are particularly difficult to control without damaging the crop.

The rising cost of propane gas is another factor to consider when deciding whether to add flaming to a weed management system. Conducting a cost/ benefit analysis is important to see if flaming is a financially viable option for an individual operation.

There are many considerations to take into account when deciding whether to use flaming as a weed control practice in any farming system. Farmers should carefully evaluate the positives and the negatives before integrating a flame-applied weed control approach into their operations.

Acknowledgements

The authors would like to thank Karen A. Renner and Christy L. Sprague for their invaluable comments in the review of this bulletin.

References

Heiniger, Ronnie W. 1998. Controlling weeds in organic crops through the use of flame weeders. Organic Farming Research Foundation Project Report. URL: http://ofrf.org/funded/reports/ heiniger_94-43.pdf. Retrieved March 2007.

Mutch, Dale, John Simmons, Jim Monroe and Gene Vogel. 2005. Some helpful tips on flaming weeds in corn and soybeans. The New Agricultural Network, vol. 2, no. 3 (May 26). URL: http://www.newag.msu.edu/issues05/05-26.htm#2. Retrieved March 2007.

Mutch, D.R., and T.E. Martin. 2006. Organic corn weed control. AoE Field Crops Team On-Farm Research and Demonstration, pp. 14-15.

Mutch, D.R., and T.E. Martin. 2007. Organic corn weed control study. AoE Field Crops Team OnFarm Research and Demonstration, pg. 12.

Row Crop Flaming Practices and Techniques. Red Dragon Agricultural Flaming Guide. URL: http://www.flameengineering.com/Agricultural_Flaming_Guide.html#practices. Retrieved March 2007.

Sullivan, Preston. 2001. Flame weeding for agronomic crops. ATTRA publication #CT157. URL: http://attra.ncat.org/attra-pub/PDF/flameweed.pdf. Retrieved March 2007.

Print

Print Email

Email