My research group have focused on developing sustainable packaging systems derived from renewable resources and mitigating the end-of-life effects of these systems. We have been uniquely innovative in three main areas of research:

Developing novel biobased and biodegradable polymers

The plastic used in packaging represents 42% of the world’s total non-fiber plastic made from fossil resources and is mainly composed of polyethylene (PE), polypropylene, and polyethylene terephthalate (PET). Use of novel biobased polymers, such as polylactic acid (PLA), poly(hydroalkanoates) (PHA), and thermoplastic starch (TPS), can help reduce our dependency on polluting fossil resources. To minimize white pollution and solve our reliance on non-renewable resources, we have been working on producing biobased and biodegradable, compostable polymeric structures that can sustain high temperatures and have high oxygen and water barrier properties; these are structures not yet in existence but highly sought after by the food and pharmaceutical industries.

Tailoring polymer biodegradability

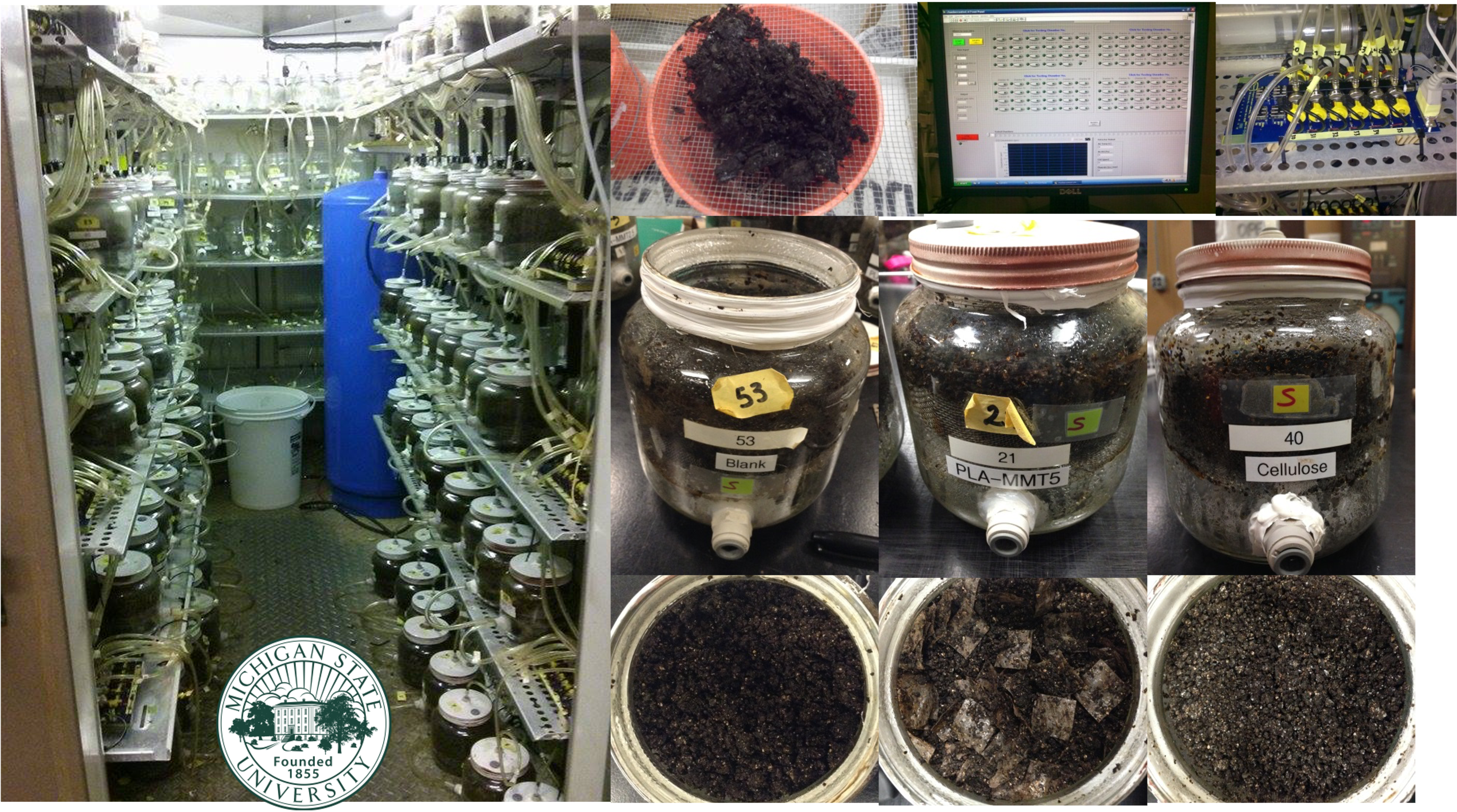

An integral part of a packaging system is its end-of-life scenario. Plastics represented almost 13% of the 292 million tons of municipal solid waste generated in the United States in 2018, from which only 8.7% was recovered through recycling, mainly PE and PET. Hence, most plastic waste (~27 million tons) ends up accumulating in landfills, some as white pollution, creating a major environmental concern and representing a missed environmental opportunity to reduce greenhouse gas emissions. Biodegradable polymers represent a promising way to divert plastic waste from landfills, with composting being an alternative disposal route to replace conventional fossil-based plastics for some applications, especially when plastic waste is highly contaminated. Disposable products used in packaging and plasticulture (i.e., plastic used in agriculture) would greatly benefit from the biodegradable features of these polymers. But such benefit is only realized if the biodegradable products are disposed of in an appropriate waste management system. Ideally, biodegradable plastics could be treated with other organic waste in composting facilities to produce compost, a valuable soil conditioner, and fertilizer. Informed with a fundamental understanding of the structures comprising these emerging biodegradable materials and their degradation mechanisms, together with my research team, I have led the design and development of equipment and methodologies and co-authored high-quality research to assess the compostability of these structures. Our research supports that fully understanding and controlling the two main stages of degradation of biodegradable polymers, abiotic and biotic phases, can help to tailor the biodegradation of these novel structures.

Designing sustainable packaging systems

As our research has centered on creating biobased and biodegradable polymers and understanding their end-of-life, a natural next step has been evaluating their environmental impact. Life cycle assessment (LCA) is the current principal methodology used to gauge the environmental footprint of processes, products, and packaging. Hence, we have used LCA to evaluate the environmental implications of adopting and disposing of specific packaging systems. We have also used novel modeling techniques, such as discrete event simulation, to model the disposal of food waste and packaging. If we can gain insight into the generation of food loss and waste, we can recommend packaging systems to reduce these losses and develop sustainable packaging systems to meet the United Nations Sustainable Development Goals (UN-SDGs).

List of Publications

A list of all our publications can be found here.

Print

Print Email

Email