Managing hop downy mildew in Michigan

Downy mildew management requires early and consistent preventative management.

Downy mildew is caused by the fungal-like organism Pseudoperonospora humuli and is a significant disease of hop in Michigan, potentially causing substantial yield and quality losses. This disease affects cones, and foliage and can become systemic; in extreme cases, the crown may die. Cool and damp weather during the spring provide ideal growth conditions for the pathogen. Disease severity is dependent on cultivar, environmental conditions and management programs. Focus on proactive management strategies, including sourcing clean planting stock, scouting regularly and utilizing a preventative fungicide program.

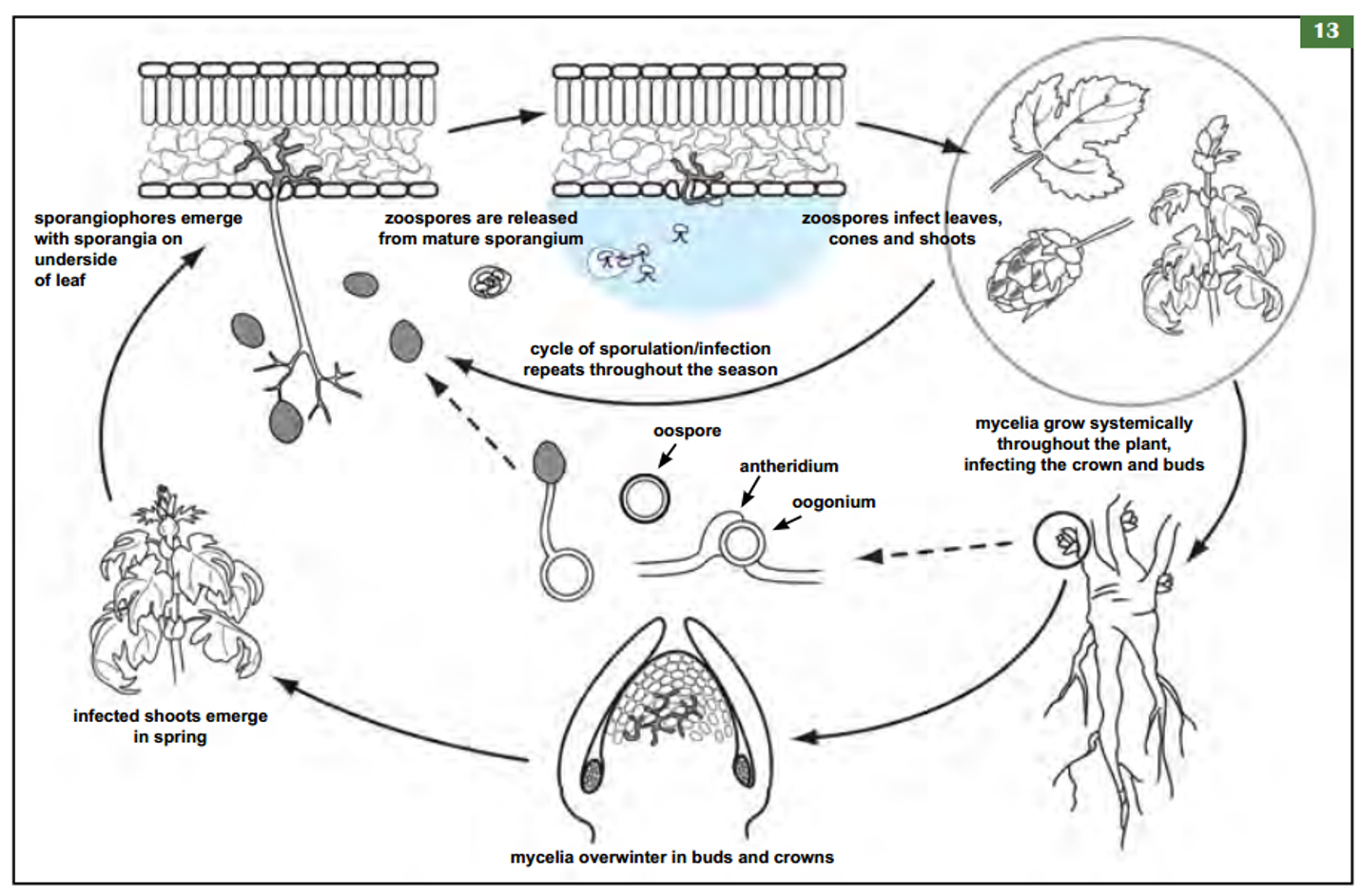

Disease cycle

The causal agent of downy mildew, Pseudoperonospora humuli, overwinters in dormant buds or crowns and can emerge on infected shoots in early spring, resulting in basal spikes. Infected crowns can produce uninfected shoots as well, making downy detection difficult, particularly on potted baby hop plants that have been cut back. The pathogen produces copious spores on the underside of leaves formed on infected basal spikes. These spores move via wind and rain onto healthy tissue and cause new infections. These new infections produce a second source of spores, which can infect all parts of the plant and reproduce continuously over the season.

Infections that occur on the terminal growing point can become systemic, growing down through the plant toward the crown where the pathogen can persist in the root system for a prolonged period. Systemic infections contribute to the spread of disease through propagation and also allow for the pathogen to survive winter, contributing to disease pressure in subsequent seasons. The pathogen can also produce a resting spore and overwinter, but it is unclear how or if these resting spores contribute to infection and how readily they are produced under Michigan conditions.

Secondary infection is favored by mild to warm temperatures (60 to 70 degrees Fahrenheit) when free moisture is present for at least 1.5 hours, although leaf infection can occur at temperatures as low as 41 F when wetness persists for 24 hours or longer.

Signs and symptoms

Primary downy mildew infections appear early in the season on emerging, infected shoots called basal spikes. Spikes are shoots growing from infected buds and appear distorted with shortened internodes that give the shoot a bushy appearance. It is easy to confuse some mild herbicide injury from glyphosate (e.g., Round Up) with downy mildew as they both produce stunted shoots. Glyphosate injury on the first flush of growth is very common, so it is important to recognize the difference. Herbicide injury will cause chlorosis that follows leaf venation and leaves will be misshapen and appear more “strappy.” Downy infected shoots will develop spore masses on the underside of leaves that follow venation. Refer to the pictures in this article.

Secondary leaf infections form angular, water-soaked lesions that follow leaf venation. Eventually, the water-soaked lesions turn brown and necrotic with fuzzy and gray-black asexual spore masses developing on the underside of infected lesions. As bines continue to expand, new shoots become infected and brittle, falling off the string. You can attempt to retrain new shoots, but you will incur yield loss as a result of missing the ideal training window. As the season progresses, symptoms may include stunted side-arm growth, tip die-back and cone discoloration. The fuzzy, visible growth of downy mildew is not always present and should not be relied upon as the sole indicator of whether infection is present.

Scouting

Scouting for downy mildew involves monitoring the crop for signs and symptoms of disease to evaluate the efficacy of the control program being utilized and gauge the level of disease pressure throughout the season. Keep records of your scouting, including maps of fields, a record of sampling and disease pressure, as well as the control measures utilized. Begin scouting as soon as plants begin to grow and continue until the crop is dormant.

To begin scouting, section your farm off into manageable portions based on location, yard size and variety and scout these areas separately. It is more practical to deal with blocks that are of the same variety, age and spacing. Walk diagonally across the yard and along an edge row to ensure you view plants from both the edge and inner portion of the block. Change the path you walk each time you scout to inspect new areas. Reexamine hotpots where you have historically encountered high mildew pressure. Weekly scouting is recommended at a minimum. Refer to the 2020 Michigan Hop Management Guide for more information about seasonal pest occurrence.

Management

Unfortunately, even when best management practices are followed, downy mildew can gain a foothold in Michigan yards due to high disease pressure, challenges with fungicide application timing, suboptimal spray coverage, fungicide wash-off, cultivar susceptibility or a combination of these factors. In addition, fungicide resistance and infected nursery plants may play a role in some disease control failures. Recent research indicates that fungicide resistance in hop downy mildew is not widespread in Michigan for popularly used fungicides with FRAC code 40. See the list of recommended fungicides below for more information on FRAC code 40 fungicides.

Use clean planting when establishing new hop yards since many insect and disease pests are readily spread via nursery stock. Consider purchasing a few plants from prospective nurseries and have them tested for diseases including mildews and viruses before committing to a large number of plants. Additionally, any other signs of poor handling at the propagator level may be used as an indicator of plant quality. Other signs of poor handling would include mite or aphid infestations, spray damage or poor root development and would be grounds for rejecting a delivery of plants.

Use a protectant fungicide management strategy to mitigate the risks of early and severe infections, but also use cultural practices to reduce disease. Keep in mind that varieties vary widely in their susceptibility to downy mildew and select the more tolerant varieties when possible (refer to Table 2 in the Field Guide for Integrated Pest Management in Hops).

On mature plants, removing the first flush of growth can help suppress disease development if disease is already present in the yard from the previous season. The early growth should be completely removed using mechanical or chemical pruning. As bines develop (8-10 feet), remove the superfluous basal foliage and lower leaves to promote air movement in the canopy and reduce the duration of wetting periods. This is commonly achieved through multiple applications of Aim herbicide or concentrated nitrogen fertilizer solutions. Aim will also control smaller weeds within the row.

Using Aim, pruning and crowning should not be performed on baby hop plants (less than 3 years old). If there is a cover crop, mow it close to the ground. If yards have no cover crop, cultivation can help to dry the soil and minimize humidity. Keep nitrogen applications moderate. For more information on pruning, refer to the Michigan State University Extension article, “Pruning hops for disease management and yield benefits.”

Apply fungicide treatments on a protectant basis as soon as bines reach 6 inches in the spring regardless of the presence or absence of visible symptoms of downy. If you are planning to remove the first flush of growth by pruning, apply the first fungicide application only after regrowth. Continue applications all season long on a seven- to 10-day reapplication interval until harvest. The time between applications may stretch longer when the weather is dry and if hop yards don’t have active infections.

Several periods in the season are particularly critical for disease control: immediately before and after training; when lateral branches begin to develop; bloom; and cone development. Covering young, developing bracts before cones close up is critical to protecting against downy mildew when conditions for disease are favorable. Getting adequate coverage on undersides of bracts where infection occurs becomes increasingly difficult as cones mature.

Refer to the table below for a complete listing of known hop downy mildew fungicide efficacy. Ranman, Zampro, Forum, Presidio (supplemental label), metalaxyl products and Revus make up the backbone of effective downy mildew management programs in Michigan. These products should be rotated and potentially mixed with Curzate and Tanos to prevent resistance development. Copper-based fungicides may also be rotated in during periods of low disease pressure and as tank mix partners. Note that Revus, Forum and Zampro contain active ingredients with the same mode of action and should not be tank-mixed or rotated and Presidio is only available via a supplemental label that growers must have on hand for legal application.

Organic growers have fewer options and will need to focus on keeping tissue protected, selecting downy mildew tolerant varieties, and following cultural practices to limit downy infection. Copper-based products are the mainstay of downy mildew management in organic hop yards and offer 5-7 days of protection but no post-infection activity. Copper should be applied ahead of any wetting events as available. The pre-harvest intervals for copper formulations vary, refer to the label. Actinovate, Eco-mate, Armicarb-O and Sonata are additional products that list downy mildew on the label and are approved for organic use in hop. The pre-harvest interval for these products are 1 day or less, at this time we have no data on the efficacy of these products.

| Hop downy mildew fungicide efficacy | |||

|---|---|---|---|

| Trade Names | Active ingredient (FRAC Code1) | Efficacy2 | REI/PHI3 |

| Forum | dimethomorph (40) | E | 12h/7d |

| MetaStar 2E, Metalaxyl 2E Ag | metalaxyl (4) | E | See label |

| Presidio5 | fluopicolide (43) | E | 12h/24d |

| Ranman, Ranman 400 SC | cyazofamid (21) | E | 12h/3d |

| Revus | mandipropamid (40) | E | 4h/7d |

| Ridomil Gold SL, Ultra Flourish | mefenoxam (4)4 | E | 48h/135d (drench) 48h/45d (foliar) |

| Zampro | ametoctradin (45) + dimethomorph (40) | E | 12h/7d |

| Curzate 60DF | cymoxanil (27) | G | 12h/7d |

| Tanos | famoxadone (11) + cymoxanil (27) | G | 12h/7d |

| Aliette WDG, Linebacker WDG | fosetyl-Al (33) | F | 12h/24d |

| Agristar Basic Copper 53*, C-O-C-S WDG, Cuprofix-Ultra 40 Disperss, Cuproxat, Mastercop* | basic copper sulfate (M1) | P/F | See label |

| Cueva* | copper octanoate (M1) | P/F | 4h/0d |

| COC DF | copper oxychloride (M1) | P/F | 48h/See label |

| Champ DP Dry Prill, ChampION++, Champ Formula 2 Flowable, Champ WG*, Kentan DF, Kocide 2000, Kocide 3000, Nu-Cop 3L, Nu-Cop 50 DF*, Nu COP 50 WP*, Nu-Cop HB*, Nu-Cop XLR, Previsto | copper hydroxide (M1) | P/F | 48h/14d |

| Badge SC, Badge X2* | copper oxychloride + copper hydroxide (M1) | P/F | 48h/14d |

| Nordox 75 WG* | cuprous oxide (M1) | P/F | 12h/- |

| Agri-Fos, Confine Extra, OxiPhos, Phiticide, Phostrol, Reliant | phosphorous acid, mono & di-potassium salts (33) | P/F | 4h/0d |

| Fosphite, Fungi-Phite, Prophyt, Rampart | potassium phosphite (33) | P/F | 4h/0d |

| Pristine | boscalid (7) + pyraclostrobin (11) | P | 12h/14d |

| Luna Sensation | fluopyram (7) + trifloxystrobin (11) | P | 12h/14d |

| Actinovate AG*, Actinovate STP* | Streptomyces lydicus WYEC 108 | 0 | |

| Folpan 80 WDG | folpet (M4) | U | 24h/28d |

| Sonata* | Bacillus pumilus strain QST 2808 (44) | U | 4h/0d |

| Trilogy* | extract of neem oil | U | 4h/0d |

| Oxidate 2.0, StorOx 2.0 | hydrogen dioxide/peroxyacetic acid | U | Until dry/5d |

| Carb-O-Nator, Kaligreen*, Milstop* | potassium bicarbonate | U | See label |

| Regalia* | Reynoutria sachalinensis extract (P5) | U | |

| Prev-Am Ultra | sodium borate | U | |

| 1. FRAC - Fungicide Resistance Action Committee (FRAC) codes are used to distinguish the fungicide groups for resistance management purposes. Consecutive applications of fungicides with the same FRAC code is not recommended. 2. 0= not effective, P = poor, F= fair, G = good, E = excellent, U = unknown. Ratings are based on published information and observations in Michigan, Oregon and Washington. 3. PHI-preharvest interval, REI-restricted entry interval expressed as h-hours or d-days. 4. Research in Michigan has shown that drench applications are more effective than foliar applications. 5. Requires a supplemental label for use in hops. * OMRI approved for organic production. |

|||

Resistance management

The downy mildew pathogen is at high risk of developing fungicide resistance, therefore careful attention to resistance management is critical. To slow the development of resistance:

- Keep inoculum low in your yard using various cultural practices. This keeps the population lower so shifts in resistance will happen more slowly.

- Rotate fungicides diligently within a seasonal spray program. Use FRAC codes to help with determining rotations. These codes can be found in the upper right-hand corner of most conventional fungicide labels or refer to the current Michigan Hop Management Guide.

- Spray on-time at the full rate and follow appropriate intervals for the product and bine development.

- Use cultural practices to improve spray coverage.

- Utilize multisite fungicides as rotational products such as Cueva (FRAC Multisite 1)

Stay in touch

Want to receive more pest management information for hop this season? Sign up to receive the MSU Extension Hops & Barley Digest or follow us on Facebook. Also, join us this summer for monthly Live Hop Production Webinar Series.

This work is supported by Project GREEEN and the Crop Protection and Pest Management Program 2017-70006-27175 from the USDA National Institute of Food and Agriculture. Any opinions, findings, conclusions or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.

Print

Print Email

Email