Lethality of Commercial Beef Jerky Manufacturing Processes

DOWNLOADMarch 18, 2020

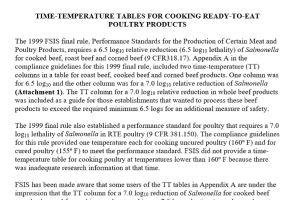

Thermal processing used in making whole-muscle beef jerky also involves drying. This drying may causeenhanced pathogen thermotolerance and evaporative cooling that reduce process lethality. Several salmonellosis outbreaks have been associated with beef jerky. In this study, a standardized process was used to inoculate beef strips with 5-strain cocktails of either Salmonella serovars or Escherichia coli O157:H7, marinade the strips in pH 5.3 marinade for 22-24 h at 5°C, and then convert the strips to jerky using various heating/drying regimes. Numbers of surviving organisms were determined during and after the heating/drying. In some trials, a commercial lactic acid starter culture was also evaluated as a potential surrogate for the pathogens. The 5-log Salmonella reduction

mandated by the United States Department of Agriculture (USDA), along with a 5-log reduction in E. coli O157:H7, was best achieved by ensuring that high wet-bulb temperatures were reached and maintained early in the process (51.7°C or 54.4°C for 60 minutes, 57.2°C for 30 minutes, or 60°C for 10 minutes) followed by drying at 76.7°C (dry-bulb temperature). Processes that met the USDA guideline with smaller safety margins were 1) heating and drying at 76.7°C (dry-bulb) within 90 minutes of beginning the process, 2) heating for successive hourly intervals at 48.9, 54.4, 60, and 76.7°C (drybulb), or 3) heating at 51.7°C (dry-bulb), followed by 76.7°C (dry-bulb) drying started before product aw was < 0.86. Achieving a > 3.0 log reduction in the starter culture is a

possible standard for validating process lethality.

Print

Print Email

Email