Bulletin E2722

Producing Garlic in Michigan

DOWNLOAD

June 30, 2016 - Questions about this information? Contact us.

The culinary uses and recent reported health benefits of garlic (Allium sativum L.) have contributed to an increased interest in garlic by consumers, growers and backyard gardeners. Interest in growing garlic has extended to regions outside typical U.S. production areas, where less is known about cultivar performance and production techniques. This bulletin presents the basics of garlic production for commercial and home gardeners in Michigan.

History

Garlic is a member of the Lily family and the genus Allium. Other members of the genus are onion (A. cepa L.), chive (A. schoenoprasum L.), leek (A. ampeloprasum L.) and several other edible and ornamental species. Elephant garlic is not a type of garlic but a bulbing leek.

Evidence of garlic cultivation can be found as far back as 3200 B.C. in Egypt. It continues to be an important part of Mediterranean, European and Asian diets as a food item, as well as a medicinal plant used to treat a variety of ailments. Recent research indicates that fresh and processed garlic may have some health benefits. Garlic is currently used for its unique flavor as a food ingredient as well as a dietary supplement. A liquid garlic spray has been used as an insect repellent for other crops.

Types

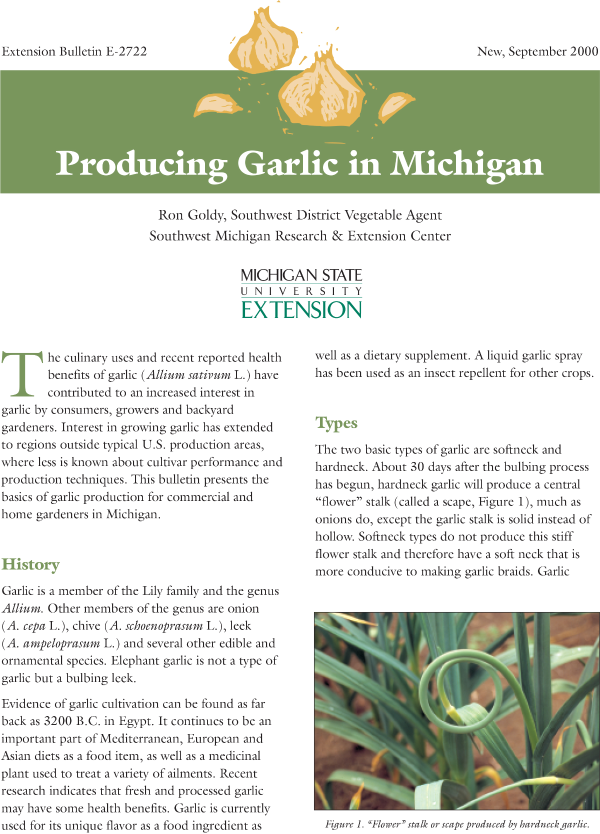

The two basic types of garlic are softneck and hardneck. About 30 days after the bulbing process has begun, hardneck garlic will produce a central “flower” stalk (called a scape, Figure 1), much as onions do, except the garlic stalk is solid instead of hollow. Softneck types do not produce this stiff flower stalk and therefore have a soft neck that is more conducive to making garlic braids. Garlic grows much like onions except it has flat rather than round leaves. The bulbing process is day length dependent. It is initiated by increasing day length in April and May. Softneck bulbs are generally less winter hardy and harder to peel, with smaller cloves, milder flavor and lower yields in Michigan trials. Softneck bulbs, however, have a longer storage life than hardneck bulbs.

Figure 1. “Flower” stalk or scape produced by hardneck garlic.

Propagation and cultivars

Garlic does not flower and produce seeds. Small bulbs (bulbils, Figure 2) are produced at the apex of the scape where flowers would normally be expected to develop. These bulbils are clones of the parent plant and can be planted for production, but garlic is usually propagated by dividing bulbs and planting individual cloves. Each clove produces a clone of the parent plant. Selection of strains by growers has led to the naming of several hundred garlic cultivars. Much sharing of cultivars occurs between garlic growers, and names can easily be lost, switched and duplicated, all of which can lead to a confusing cultivar situation.

Figure 2. Bulbils produced at the tip of the scape.

Because garlic does not produce seed, breeders cannot breed and develop cultivars specific to growing regions. Cultivar testing by Michigan State University began in 1996 at the Southwest Michigan Research and Extension Center near Benton Harbor to find those best suited to Michigan conditions. In these trials, ‘Music’, ‘German White’ and ‘Polish Softneck’ have performed satisfactorily and can be recommended for commercial production in Michigan. Do not plant large amounts of an untried cultivar until it has shown promise for two or three growing seasons.

|

Cultivars: The two types of garlic are softneck and hardneck (also called topset or stiffneck). Softneck types generally are earlier maturing and white, have a longer storage life and are easier to braid. Softnecks, however, are harder to peel, have small cloves (especially near the center of the bulb) and have small seed cloves. Hardneck types have four to eight cloves arranged around a central stalk, are easier to peel, more winter hardy and later maturing, and have more usable garlic and larger seed cloves. The disadvantages of hardnecks are purple pigment in the skins and shorter storage life. From Michigan yield trials the following cultivars can be recommended. German White: Hardneck with white skin with some purple striping. It has six to eight large cloves per bulb, medium maturity and good storage life. It has a strong, pungent, hot flavor. Yield will generally be about five to six times the weight planted, with many bulbs being 2 to 2 1/2 inches in diameter. Music: Hardneck with white to lightly pink skin with some purple striping. It has four to six large cloves per bulb, medium maturity and good storage life if grown in cold climates. It has excellent flavor, pungent but not too hot. Yield will be about four to six times the weight planted, with many bulbs being 2 inches in diameter. Polish Softneck: Softneck with a white outer skin with some purple stripes on the inner skin. It can have 12 to 20 cloves per bulb and has later maturity and excellent storage life. It usually has a strong, hot flavor. Yield can be seven to eight times the weight planted (although it has not been this high in Michigan trials), with many bulbs being 1 1/2 to 2 inches in diameter. Good for braiding. |

Planting stock should be stored at 50° F and no more than 60 percent relative humidity. Lower temperatures cause rapid sprouting, side shoots, rough bulbs and early maturity, all of which lead to reduced yields. Higher temperatures shorten storage life and increase disease potential during storage. Bulbs sold for table use have been stored at temperatures near 32° F and should not be planted.

It is important to obtain planting stock from a reputable dealer who can provide true-to-name, disease- and nematode-free stock. The reputation of a seed stock grower may be difficult to establish. On-site visits to production fields are helpful but not always possible. Ordering small amounts of the same cultivars from different sources will allow quality comparisons between sources. When the stock arrives, inspect it for external appearance and mold symptoms under the skin and between cloves. Also look for damaged root plates (the area where the roots attach to the bulb). Plates should not be discolored or soft, and roots should not be easily removed. Any of these problems could indicate the presence of fungi. If the stock is badly infected, do not plant it. Keep material from each supplier separate and observe how it grows during the season. Once you have quality planting stock, it is possible to increase it yourself to the point where you have enough plant material for sales and for replanting. Do not be tempted to sell your best material — keep that for your planting stock for next year.

Soil and site preparation

Garlic can be grown in a wide variety of soil types, provided they are well drained. Sandy loams are best because of their water-holding capacity and generally good drainage. Clay soils are suitable if they can be loosened enough so as not to inhibit planting and bulb growth. Soils high in sand are suitable if adequate water for irrigation is available. High organic soils should be avoided because of the high potential for frost heaving during the winter and the seasonally high winter water table. Clay and organic soils also tend to adhere to and/or stain the outer skins, which decreases marketability. Garlic is susceptible to the same pest problems as onions and other Allium species. Therefore, avoid planting garlic in fields where onions have been planted within the past two years.

Garlic grows best at a soil pH of 6.5 to 7.0. Lower pH levels inhibit plant growth, and soil pH below 5.0 can actually lead to plant death. A general soil test should be performed before planting to determine pH and nutrient availability.

If lime is needed, it should be applied according to soil test results and incorporated. The soil should be well worked at least 10 inches down. Some sites may need to be subsoiled if a hardpan has developed at the bottom of the plow layer. Garlic roots extend several inches into the soil, and a hardpan too near the surface can restrict root penetration and the plants' ability to obtain water and nutrients.

The first step in site preparation is controlling annual and perennial weeds. This can be accomplished by cultivation and/or herbicide application. Site preparation should begin at least two to three months prior to planting in new fields. Starting early provides several opportunities for cultivation or two applications of a broad-spectrum contact herbicide, if necessary. When using a field currently in production, review the herbicide program used on the current crop to be sure there will be no detrimental carryover. Spring planting of a legume cover crop such as an annual clover will help reduce weed problems and build the soil with nitrogen and organic matter.

Planting

Garlic is planted in the fall — ideally, six weeks before the ground freezes. Depending on your location in Michigan, this is generally some time in October. Spring planting can be done, but yields will be greatly reduced, and it may be difficult to store planting stock this long. The goal is to get only root development before winter. If shoots do emerge shortly after planting, they will be killed back by the cold and the plant will have wasted energy. Three factors usually result in shoots emerging too soon: the cloves were planted too early, they were not planted deep enough or the cultivar is not well adapted to the area. Fall emergence of shoots is controversial — some growers indicate they get early shoot emergence without significant loss of yield.

Plant spacing depends to a certain degree on available equipment and how it might be adapted to garlic production. Planting schemes range from single rows 40 inches apart to double-row raised beds on 36-inch centers and rows 12 inches apart. In-row spacings range from 1 to 6 inches. Tighter plantings are usually used for garlic grown for processing, where the main interest is in total yield. The fresh market demands a larger bulb, which requires increased between- and in-row spacings to produce. A suggested planting scheme is shown in Figure 3. This shows double rows 36 inches on center with 12 inches between the two rows. An inrow spacing of 4 inches is a good general spacing for most cultivars grown for fresh bulb production. With this spacing, each plant has 1/2 square foot for growth, with a plant population of 87,120 per acre. Cloves planted for the green garlic market can be planted at tighter spacings because they will be harvested before bulbing. At this time, there is no processing market for Michigan-grown garlic.

Figure 3. Garlic planted in a double-row system with a spacing of 12 inches between rows and 36 inches between double rows.

For hand planting, rows can be made using cultivators properly spaced and set at the right depth (Figure 4). After planting, the cloves can easily be covered with a hand hoe. The planting process has been mechanized by adapting potato or other planters to handle garlic. However, high-quality fresh garlic is generally hand planted (Figure 5). For bulb production, cloves should be placed from 2 to 4 inches deep with the root plate down and the point up (Figure 6). For green garlic production, cloves can be planted closer together and either planted 6 inches deep or planted shallower and mounded up so a significant portion of the stem remains white.

Figure 4. Marking and digging double rows with a cultivator.

Figure 5. Hand planting garlic cloves.

Figure 6. Proper spacing of garlic, placing root plates down.

When determining how much seed garlic is needed, a good rule to follow is that hardneck types will have about eight bulbs/pound and six to eight cloves/bulb. So there will be about 55 plantable cloves per pound. The planting scheme of one clove per 1/2 square foot would require approximately 1,600 pounds of seed garlic/acre. Actual numbers will vary with cultivar. Before planting, bulbs must be separated into individual cloves (Figure 7). This must be done just prior to planting because separated cloves are more prone to disease and drying out and do not store well. Hand separation is best because it minimizes damage to the cloves and provides an opportunity to inspect cloves for disease problems. For hardneck garlic, the hardest part is to remove the outer skin and the first clove. Once the first clove is removed, others can be removed much easier. Various tools can be used to break through the outer layers of skin to remove the first clove. Be careful not to damage any cloves in the process. Some growers use an air compressor set to deliver 50 to 100 pounds pressure controlled by a foot valve. This will blow off the outer skin and help loosen the cloves. (CAUTION: Make sure to wear protective eye covering.) The layer of skin around the individual cloves does not need to be removed.

There is a direct correlation between clove size and resulting bulb size; small cloves produce small bulbs and large cloves produce large bulbs. Knowing this, growers of fresh market garlic should plant only the largest cloves. What constitutes a large clove is somewhat arbitrary (Figure 7). A separator for small quantities can be easily made from a 2-foot-square frame made of 1- by 4-inch lumber with the proper size screen tacked to it (Figure 8). Figure 8 shows the use of a 5/8-inch screen which allows cloves with diameters smaller than 5/8 inch to pass through (Figure 9). Other screen sizes can be used to separate out different clove sizes. Cloves too small for planting for bulb production can be eaten or planted for green garlic production.

Figure 7. Cloves should be separated and graded into sizes just prior to planting.

Figure 8. Screen separator (5/8-inch) used to size cloves prior to planting.

Figure 9. Cloves separated by screening.

Many reports indicate the need for a 2- to 4-inch layer of mulch applied immediately after planting. The purpose of the mulch is to provide winter protection and weed and moisture control. The need for mulch for winter protection is questionable in areas that receive adequate snowfall or have minimal soil freezing during the winter.

The whole process of clove separation, sizing and planting has been mechanized. Many growers of fresh garlic avoid mechanical separators because they can damage cloves. Sizers consist of a tilted, rotating drum with smaller holes at the entrance end and larger holes at the exit end of the drum. Mechanical planters operate by simply dropping a clove into a furrow and covering it up. Most cloves get planted on their side rather than base down, as desired. Growers will have to decide when the size of their planting warrants each step in mechanization.

Fertilization and water needs

Garlic responds to fertilizer applications, and care must be taken when following recommendations. Much of the research on garlic fertilization comes from California, where recommended rates are high because of the longer growing season. The plants may be in the ground just as long in Michigan, but growth is greatly reduced from December to March, and nutrient applications have a greater risk of leaching rather than being utilized by the plant.

Fertilizer recommendations have not yet been fully established for garlic in Michigan, and rates recommended for onions are generally too high. Nitrogen is needed primarily for vegetative growth, so applications should be limited to 25 pounds/A nitrogen as a preplant application in the fall. Follow the phosphorus and potassium recommendations of the soil test. If a soil test has not been done, phosphorus at 150 pounds/A and potassium at 100 pounds/A should also be applied and incorporated before planting. Additional applications of nitrogen should be made the following spring, with 40 pounds/A applied in March or early April when the garlic starts to grow, and another 40 pounds around May 1. The goal of fertilizer applications is to grow as vigorous a plant as possible prior to the initiation of bulbing in mid-May. Once the bulbing process has begun, little response is seen to additional fertilizer applications. Ammonium nitrate is the desired form of nitrogen. Some reports recommend avoiding urea forms.

Composted manure also provides a source of fertilizer. Actual amounts will vary, depending on the animal source, and care should be taken not to overapply. Growers using manure must be aware that they could potentially increase weed problems if the manure has not been properly composted. Proper composting is also necessary to reduce human health concerns.

Garlic requires between 1 and 2 inches of water per week. Like nitrogen, water will have its greatest effect on yield prior to bulbing. Soil moisture conditions are usually adequate during March, April and May, when garlic growth is most rapid, but care should be taken to compensate for occasional dry periods during this time. Adequate moisture is still needed after bulbing, but irrigation should be stopped at least two weeks prior to the expected harvest date. Late-season irrigation tends to stain the skins and reduce quality.

Scape removal

The scape is the plant part that produces the garlic “flower.” Scapes will emerge from the center of the plant in mid-June. They start out straight and curl as they elongate (Figure 1). They will straighten out again as they mature and can reach a height of 5 feet (Figure 10). The scapes will not produce a flower but produce bulbils (Figure 2), which are clones of the parent plant. Producing scapes and bulbils can take energy away from the developing bulb and can reduce bulb yields as much as 30 percent.

Figure 10. Scapes can reach 5-feet tall and should be removed before they straighten out.

To avoid yield reduction, scapes should be removed. Scapes can be removed by hand either by breaking, cutting or pulling them from the plants. This should be done shortly after emergence but before they straighten out from their curl stage.

If removed at this time, they are still succulent and can be used fresh or in cooking (see section on harvesting). Pulling results in a larger scape, but care must be taken not to pull the plant out of the ground.

Pest control

Garlic is susceptible to the same pest problems as onions but generally to a lesser degree. Proper crop rotation can greatly reduce many pest problems. Garlic is not a good competitor, so weed control is a necessary part of successful garlic production. Problem weeds should be controlled before planting.

Few weeds appear after planting in the fall. The biggest problem occurs the following spring. Mechanical cultivation is possible between the rows, but hand hoeing will have to be done within rows. Mulches also reduce weed pressure, but be careful not to put on so much mulch that it interferes with garlic emergence. Herbicides can also be applied. For the latest recommendations, please refer to Extension Bulletin E-433, Weed Control Guide For Vegetable Crops, available from your local MSU Extension office.

Insects of concern to garlic production are thrips and onion maggot. Thrips feed on leaves, causing a general yellowing of the leaf. Thrip activity is hard to observe because of their small size, and much damage can be done before the pest is identified. Thrips are yellowish, about 1/16 inch long and best found between leaves. They damage the plant by chewing on the leaf surface and feeding on the plant sap. Damage first appears as silvery blotching that will turn yellow and then brown as the tissue dries up.

Onion maggot is a fly that lays eggs on the ground near the plant. The eggs hatch and the larvae crawl to the developing bulb and burrow into it. Wilting is the first symptom in infested plants. If infestation occurs early in the season, the plant may be killed. If it happens late in the season, the bulbs will be unmarketable and will usually have a soft rot associated with the insect. Onion maggots are often attracted to bulbs that have been damaged by other problems, such as root rot. Corn borers have been found boring down stems after the scapes have been removed, but this activity occurs late enough that it does not cause economic damage.

The diseases most prevalent in garlic are green mold (Penicillium sp.), basal plate rot (Fusarium sp.), pink root (Phoma sp.) and sclerotinia rot (Sclerotinia sp.). Garlic has not been in production long in Michigan, so it remains to be seen what diseases it will contract. The biggest problem so far has been with basal plate rot. Plants infected with basal plate rot will show earlier maturity and roots that can easily be removed from the basal plate (Figure 11). The disease will eventually spread into the cloves and make them unmarketable. Green mold is often seen when separating cloves. It can be a severe problem if the cloves for planting have been roughly handled and bruised.

Figure 11. Basal plate rot caused by Fusarium.

The best way to control diseases and insects in garlic is to follow sound rotation practices, plant only clean seed stock and maintain healthy plantings through proper water and nutrient management. A number of insecticides and fungicides can be used to control these pests. For the latest recommendations, please refer to the latest edition of Extension Bulletin E-312, Insect, Disease and Nematode Control for Commercial Vegetables available from your local MSU Extension office.

Harvest

Three products can be harvested from garlic: scapes (Figure 12), green garlic (Figure 13) and bulbs (Figure 14). Scapes and green garlic are not recognizable by most people because they are not products sold in supermarkets. Some education and free samples may be needed to help market these items.

Figure 12. Harvested scapes.

Figure 13. Freshly harvested green garlic prepared for sale.

Figure 14. Cleaned and graded bulbs prepared for sale. Left to right: large, medium and small bulbs.

Scapes are ready for harvest when they have completed their circle. Once they start to uncurl, they get fibrous and unusable. Scapes can be used in a variety of ways in fresh or cooked products. The flavor is milder than that of the cloves but is still uniquely garlic. Scapes are harvested by pulling, breaking or cutting them off the plant. Those that are pulled off tend to break off down inside the leaf sheath, and a significant portion of the scape will be white. This will increase the size of the harvested material and is desired by certain ethnic groups who are familiar with using scapes. Pulling can be done only on the healthiest plants; otherwise, the plants can be pulled out of the soil.

Green garlic is simply garlic that has been harvested prior to bulbing. This product has much the same appearance as green onions (Figure 13) and can be used in a similar way in salads or cooking. It is milder flavored than bulbs. Green garlic from fall-planted bulbs is available from late April to early June, depending on the cultivar. Early spring-planted bulbs can extend the season somewhat, but later planted bulbs do not have the stem growth desired. Cloves for green garlic production can be those cloves too small for bulb production.

Green garlic can be harvested anytime in the spring when the plants are large enough. This may be as early as late April. Green garlic harvest may continue until early June or later if cloves were planted in late spring. Once garlic has begun the bulbing process, the base will begin to swell, the scape will form and they will lose their appeal as green garlic. Bulbing is day-length dependent, so late-planted cloves get the signal at the same time as early-planted ones, and they will not be too far behind established plants in their bulbing response. To harvest green garlic, loosen the soil and pull out the plants. Roots should be trimmed to 1/4 inch and the leaf tips trimmed, if needed. Cutting the roots completely off will detract from the appearance by allowing the leaf sheaths to elongate.

Bulb harvest will usually take place during July. Maximum yield and maximum quality are two different goals. Maximum yields are obtained by allowing plants to grow as long as they can. If allowed to grow too late, however, the cloves will expand to the point that the skins will split, which lowers quality. Bulbs are harvested when 30 to 50 percent of the leaves have died back. This stage will allow for the best yields and best quality.

Garlic bulbs should be harvested when the weather is dry. In small plantings, it can be harvested simply by taking a shovel and loosening the soil next to the plants and pulling them out. Laying them on the ground and leaving them to dry for a few days will help dry the soil adhering to the roots, and much of it will fall off when the plants are picked up. Harvest of larger plantings is similar to onion harvest. To loosen them from the soil, a cutting bar is passed down the row underneath the plants. Once loosened, they can be hand pulled and placed into windrows. Several rows of garlic can be placed in each windrow. If the weather is expected to be dry, plants can be left out to dry further for up to a week. To minimize sunburn, hide the bulbs under the tops as much as possible. After field drying, tops and roots are removed before or after storage. Tops and roots are removed by hand, leaving 1/2 inch of the root and 1 inch of the top.

If a section of the planting is to be grown only for seed production, it could be allowed to mature more than bulbs grown for consumption. This will make clove separation somewhat easier. If left in the field too long, however, cloves may separate from the basal plate at harvest.

Drying and storage

In humid growing regions such as Michigan, further curing after harvest may be needed. If moisture can be squeezed from the cut stem, more drying time is necessary. Plants placed into curing conditions with tops still attached will take longer to cure than those that have the tops removed. Curing in larger volume storage containers will also take more time. Containers need to have fairly open sides and bottoms that will provide for the free movement of air. Garlic should not be stacked more than 3 feet high in the container. Forced ambient air at a rate of 5 cu ft/min/cu ft of garlic will significantly reduce drying time. Small amounts can be bundled together and hung to dry in a well ventilated area away from direct sunlight.

Storage conditions depend on the intended use. If the garlic is to be used as planting stock, it should be stored at 50o F at a relative humidity of 60 percent or less. Temperatures lower than this will cause physiological changes in the cloves that will lead to reduced yields. At higher temperatures, molds can become a problem. Storage for consumption is similar to onion storage. Once cured, it is best to store garlic near 32o F at 65 to 70 percent relative humidity. Higher humidities and temperatures lead to greater storage problems. Root development is pronounced at 40o F, especially under high humidity. Stored bulbs continue to transpire, so adequate ventilation is needed to control humidity.

Storage times of scapes and green garlic are not as long as for dried bulbs. Both products need 32o F and 95 to 100 percent relative humidity. In these conditions the products will stay in good shape for three to four weeks.

Grading and marketing

Garlic is graded on the basis of appearance and size. Poor-looking bulbs with missing or diseased cloves or split or badly stained skins are graded out. Bulbs with good appearance are graded into size categories based on diameters of large (>2.5 inches), medium (2.0 to 2.5 inches) and small (<2.0 inches) (Figure 14). Another category, Jumbo (>3.0 inches), can be added if enough bulbs reach that size.

Scapes and green garlic should be graded into similar sizes. Green garlic can be put in bundles of similar-sized plants and banded together. Scapes can be placed into bulk containers or into plastic containers that hold a known weight.

Marketing Michigan-grown garlic is left up to individual producers, and it is something they need to consider and establish, even before planting. Direct marketing through farmers' markets is probably the best approach at first. Ethnic and upscale restaurants are probably the best outlets for green garlic and scapes. Many chefs are looking for different and unusual items to use in their entrees. Green garlic and scapes can be eaten fresh in salads or cooked. In cooked dishes, it will take more product to get the desired garlic flavor, so it is a visible part of the entree as well as a flavoring. Green garlic leaves can also be used. If you are in a high-traffic area, roadside marketing is another possibility. Whether the traffic is due to population centers or to tourists, be sure to offer a variety of garlic products.

Garlic bulbs can be sold individually or in varying amounts placed into nylon mesh bags or boxes. Make sure to keep cultivars separate so customers can keep track of the various cultivar characteristics. You may want to offer a “variety pack” of three or four different types. The best way to suggest that customers sample the cultivars is by roasting the garlic and spreading it on fresh bread or crackers.

Michigan has several onion packing operations, and packing and marketing garlic would be a natural use of their equipment and marketing channels. It would take a sizable increase in acreage to be able to justify this.

Organic production

Growing garlic organically is also a possibility. The trials at the Southwest Michigan Research and Extension Center have been grown without fungicides or insecticides. Nutrients can be provided through composted manure applications, legume cover crops and other alternative sources. Weeds can be controlled through mulch applications or cultivation. Proper crop rotation is critical in organic production, and garlic should not be planted in areas that have had any Allium species within the past two years or, better yet, three. This reduces potential disease and nematode problems. Remove diseased plants as soon as they are identified. Maintain healthy plants through proper nutrient and water management. This is particularly important for management of onion maggot. Onion maggot adults are capable of locating stressed plants. Healthy plants are not as attractive to them.

Organic garlic commands a higher price than nonorganic garlic. Certain requirements must be met for a crop to be labeled as certified organic. Contact your local MSU Extension office for information on becoming a certified organic grower.

Economics

Potential growers should not plant garlic without first considering the cost. Garlic production requires a fair amount of hand labor and can be expensive. First-year expenses are usually higher than subsequent years because of purchase of seed stock. Seed stock ranges from $3 to $9/pound, with price depending on the amount purchased, the cultivar and whether it was grown organically. Because of this high cost, many growers start with a small amount (200 pounds) and increase their own stock. This is a wise option for first-time growers because it allows time for gaining production experience and establishing markets. When increasing seed stock, care must be taken to maintain high standards in record keeping and control of disease and other potential pests.

Actual inputs and returns will vary substantially, depending on equipment already available, intended market, quantities planted and harvested, family labor vs. hired labor, and many other factors. Recent figures from Ontario suggest that garlic costs approximately $1/pound to purchase and prepare seed stock, produce, harvest, cure and market. Organic garlic production will likely be higher than $1, but returns will also be higher.

Expected yield from garlic grown for bulbs is about 6 pounds for every pound planted. With 1,600 pounds/A planting stock, yields of 9,600 pounds can be expected. Out of that 9,600 pounds, about 1,000 pounds will be culls and another 1,600 pounds will be saved for replanting. That leaves 7,000 pounds/A to market. This does not include yields from scapes, and it assumes all cloves planted went for bulb production and not for green garlic.

At these numbers, the break-even price is $1.37/pound, a number easily attainable. At $2/pound, a profit of $4,400/A would be realized. Scapes are an additional crop from the same bulbs, so any income from those would make that much more profit. High-quality scapes (those that have been pulled and have a large portion of the scape white) can be sold for between $3 and $5 a pound if there is a market that can utilize them.

At $2/pound, each bulb is worth about 25 cents. So green garlic has to recover at least this cost if the garlic was intended for the bulb market. A fair amount of hand labor is involved in preparing green garlic for market, therefore a return of $2 for a bundle containing four or five plants is needed.

Print

Print Email

Email