Scaling Up Production of Local Salad Mix for Retail Grocery Markets: A feasibility study in Southeast Michigan

DOWNLOADOctober 28, 2021 - Mariel Borgman, Michigan State University Extension; updated from study by Jae Gerhart

Introduction

Changes to the supermarket supply chain over the last few decades have "squeezed out" local and small farmers in place of more consolidated and global suppliers. As a result, local farmers have turned to more direct-to-consumer markets (e.g., farmers markets, farm stands, subscription models) for sales, which capture a higher price point but also bear higher marketing costs.

Research indicates direct markets are potentially saturated and have low profit margins.

Scaling up

Researchers have explored strategies for "scaling up" local farmers into intermediary supply chains, such as grocery retail, with positive results.

Common "scaling up" strategies include:

- upgrades in harvest technology

- centralized packing and/or processing

- producer and buyer collaboration

- producer cooperatives

This research is unique in that it uses production costs to test the feasibility of "scaling up."

Production costs

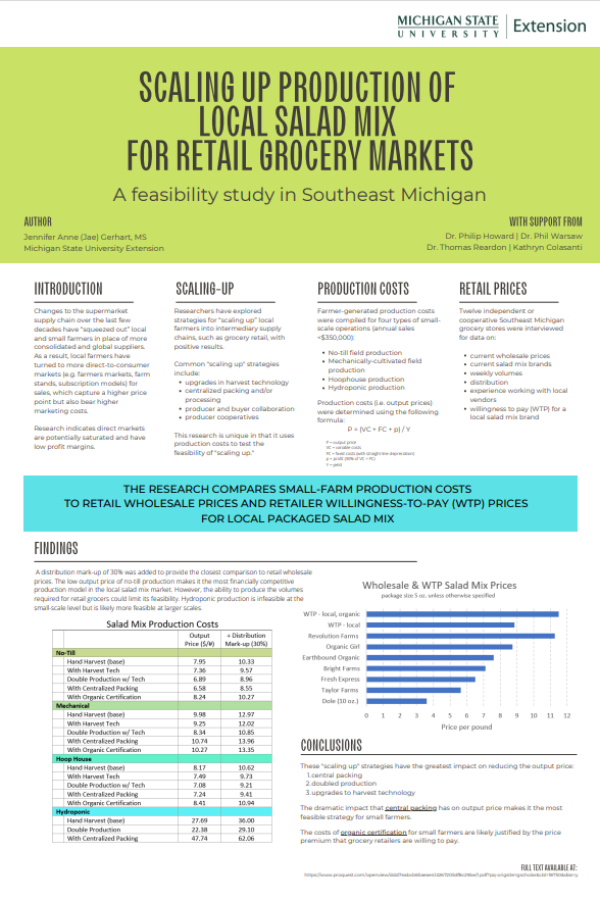

Farmer-generated production costs were compiled for four types of small-scale operations (annual sales <$350,000):

- No-till field production

- Mechanically-cultivated field production

- Hoophouse production

- Hydroponic production

Production costs (i.e., output prices) were determined using the following formula:

P=(VC + FC + p) / Y

P = output price

VC = variable costs

FC = fixed costs (with straight-line depreciation)

p = profit (30% of VC + FC)

Y = yield

Retail prices

Twelve independent cooperative Southeast Michigan grocery stores were interviewed for data on:

- current wholesale prices

- current salad mix brands

- weekly volumes

- distribution

- experience working with local vendors

- willingness to pay (WTP) for a local salad mix brand

Findings

A distribution mark-up of 30% was added to provide the closest comparison to retail wholesale prices The low output price of no-till production makes it the most financially competitive production model in the local salad mix market. However, the ability to produce the volumes required for retail grocers could limit its feasibility. Hydroponic production is infeasible at the small-scale level but is likely more feasible at larger scales.

Conclusions

These "scaling up" strategies have the greatest impact on reducing the output price:

- central packing

- doubled production

- upgrades to harvest technology

The dramatic impact that central packing has on output price makes it the most feasible strategy for small farmers.

The costs of organic certification for small farmers are likely justified by the price premium that grocery retailers are willing to pay.

Print

Print Email

Email