Developing biodegradable plastics to reduce negative environmental impacts

Conventional plastic can take over 1,000 years to degrade. Rafael Auras believes this can be solved through biodegradable and compostable materials.

Around the dawn of the 20th century, scientists were hard at work developing one of the most influential products in history — plastic. It was easily manufactured at a low cost and could be used for various purposes. Because of these desirable traits, plastic became a common material in the construction of just about everything.

The surge in plastic products continues today, but there’s a catch: Its proliferation into virtually every market has created a surplus. Americans toss out more than 30 million tons of plastic each year, with less than 10 percent getting recycled.

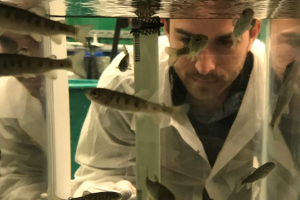

Because of its molecular structure, conventional plastic can take upwards of 1,000 years to degrade in a landfill. Rafael Auras, an associate professor in the School of Packaging at Michigan State University (MSU), believes this is a problem that can be solved through utilization of biodegradable and compostable materials.

Upon his hiring at MSU in 2004, Auras decided that a primary component of his research would be biodegradable plastics. First, Auras wanted to test the compostability and degradability of existing biopolymers. To do so, he needed a way to simulate several climate conditions in the lab.

Auras and his team have created a chamber that holds numerous samples, in which the temperature and other environmental conditions can be easily altered. Contained within each sample is soil — home to microbes that break down the plastics — and the biopolymer. Auras said that the initial stages of the research have highlighted the complexity surrounding this topic.

“There are a huge number of factors that go into the biodegradation of a biopolymer,” Auras said. “We have to think about the chemical structure and facilitating the breaking down of that structure with the help of microbes. There are other important aspects — temperature, pH and moisture levels. High-moisture environments encourage degradation, for example. When we think about developing new biopolymers, these are the things we’re considering.”

Auras believes that biodegradable plastics could revolutionize the food packaging industry.

“One of the biggest offenders in plastic pollution is food and beverage packaging,” Auras said. “When contaminated, these plastics can be hard to clean and many recycling centers won’t accept them, so they are thrown away. If we can create a type of widely adopted, biodegradable food packaging, we can drastically reduce the amount of plastic that ends up in landfills.”

But Auras is interested in more than food containers. Agricultural uses of plastic include mulch films, which suppress weeds, retain soil moisture and soil bed structure, and control soil temperature, among other benefits. Mulch films have traditionally been made of petroleumbased, non-biodegradable plastics. After use in the field, it is costly to remove and recycle them.

Biodegradable films deteriorate throughout the growing season, and then farmers plow the remainder into the soil to finish the degradation process. To test the efficacy of biodegradable films against that of their conventional counterparts, Auras and collaborators performed a study placing three mulch films over the beds of tomato plants, with funding from MSU Project GREEEN (Generating Research and Extension to meet Economic and Environmental Needs). Two of the films — one black and one white — were biodegradable; the third was nonbiodegradable.

He found that the white biodegradable film was compromised quickly, primarily through sunlight damage (photodegradation), resulting in poor performance. The black film, however, maintained its structure longer and was comparable in weed suppression to the conventional plastic. Yields of tomatoes were similar between the black and conventional samples, and the cost of removal and disposal was replaced with plowing the leftover film.

The primary criticism of the black film was crosslinking — molecular bonds that occurred as a result of photodegradation. This promoted brittleness that damaged the film, but slowed overall degradation. Therefore, Auras developed a film formulation that can be used in Michigan with a reduced rate of crosslinking.

“The technology holds real promise, but there are obstacles to overcome,” Auras said. “It would be a significant cost savings for farmers if they could avoid removing and recycling non-biodegradable films. What we have to figure out now is how we can take advantage of the optimum conditions for effective degradation while also ensuring that the films serve their purpose adequately.”

Although they’ve existed for many years, biodegradable plastics have yet to establish a foothold in the marketplace. Auras said it’s imperative to consider the abundance of factors that affect consumer behavior, such as price, quality and availability.

“We know that people are willing to pay a little extra for products that are designed to be environmentally conscious, but they won’t make decisions that reduce convenience,” Auras said. “These products have to be readily available and easy to obtain because consumers are not willing to sacrifice their time in most cases.

“Additionally, it’s important to show people how they can create positive social and environmental outcomes by purchasing everyday products.”

Print

Print Email

Email