MSU Packaging faculty plays vital role in NSF proposal to advance circular packaging economy

Laurent Matuana, a professor and associate director in MSU’s School of Packaging, is part of a team at MSU forging a path toward a sustainable circular packaging economy through a recent proposal to the National Science Foundation

A team of researchers and academics at Michigan State University (MSU) are forging a path toward a sustainable circular packaging economy through a recent proposal to the National Science Foundation (NSF).

Their proposal is among 71 teams selected to advance to the next stage of the NSF Regional Innovation Engines program. This effort solicits annual proposals to address national challenges, cultivate partnerships and stimulate economic growth. The program plays an essential role in advancing sustainable technologies, with particular interest in supporting initiatives in regions that have yet to fully participate in the modern technology boom.

MSU Research Foundation and MSU, in partnership with Ohio State University and other collaborators, developed the Sustainability Hub for an Alternative Packaging Economy (SHAPE) proposal. This proposal aims to establish the Great Lakes Region as a global leader in the circular economy for packaging. With its unique environmental and economic characteristics, the Great Lakes Region presents significant challenges and opportunities for sustainable packaging solutions.

In April 2024, SHAPE received a $1 million NSF Engines development award. These awards support recipients in establishing the foundation for a new NSF Engine focused on a specific region and topic area. During the development phase, recipients build the initiative’s structure, scope and partnerships. By the end of the award period, they are expected to be well-prepared to advance to the nascent phase and secure additional NSF support to develop their regional innovation ecosystems further. SHAPE’s advancement to the next stage of the Regional Innovation Engines program positions it for consideration of a Type 2 Engines award, which could provide up to $160 million in funding over 10 years to support the continued growth of the initiative.

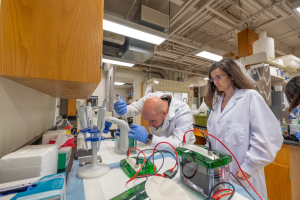

Dr. Laurent Matuana, a professor and associate director in MSU’s School of Packaging, serves as a co-principal investigator and site director of research and development for SHAPE. A Fellow of the Society of Plastics Engineers with an extensive career developing sustainable packaging applications to improve on the shortcomings of existing materials, Matuana sees immense value in SHAPE’s mission to foster a circular packaging economy.

“Essentially, through current processes and waste, we are destroying our environment,” said Matuana. “That’s why SHAPE is working on a sustainable approach to easing the production of harmful packaging materials. We’re working to reduce the impact of packaging, like plastic and paper, on the environment and people's lives. We are creating new material and designing it for recyclability, and as they will be bio-based and sustainable, they will be better for the environment and public health.”

SHAPE aims to drive economic development through effective waste reduction strategies, with a vision of creating a world free from paper and plastic packaging waste. The program is built on three strategic pillars: developing new reclaimable materials that meet packaging manufacturing needs, stimulating innovation to enhance economic opportunities and promoting collaboration among industry, government, academia and non-profits to tackle waste challenges.

By addressing these objectives, SHAPE is poised to deliver substantial environmental, economic and social equity benefits while further positioning the Great Lakes Region, particularly Michigan and Ohio, as a sustainable model for packaging practices.

Currently, the U.S. produces more plastic waste than any other country, with the packaging sector being the leading contributor. Only a small fraction is recycled in the U.S., resulting in significant environmental and public health concerns. PFAS, manufactured chemicals that break down very slowly, and microplastics, small plastics produced during degradation, pose specific risks. These accumulate in humans, animals and the environment over time and have been linked to adverse outcomes.

The SHAPE initiative has sparked a collaborative process with key stakeholders in packaging and related industries, underscoring the proposal’s fundamental goal of building on user-inspired research. By engaging informed stakeholders to understand and fulfill the requirements of consumers and manufacturers, SHAPE is well-positioned to develop innovative solutions that address existing challenges while ensuring that new products are competitive in the marketplace. The materials and production techniques expected to result from the initiative will have added benefits in creating new regional jobs.

“This is fundamental research in the lab that will benefit society moving forward. The technology we’re developing will be translated and commercialized, creating the need for specialized jobs and fostering economic resilience,” said Matuana. “While working to help the environment and improve public health, we’re also training the next generation and creating new jobs. Being surrounded by our stakeholders is what allows that to happen. Without them, we aren’t truly an Engine.”

Print

Print Email

Email